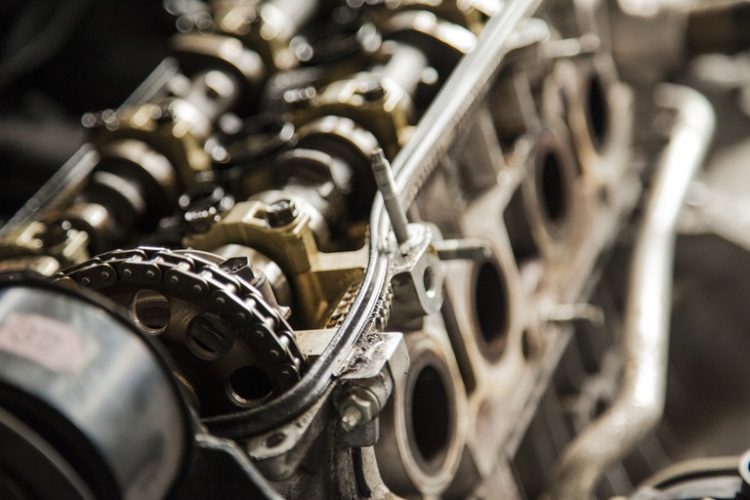

Man’s quest to be mobile led to the invention of the Internal Combustion engine. It is a significant invention of our times. Throughout the century it has evolved in leaps and bounds and continues to do so today. However, the research and development is now more focused on the way the Fuel-Air mixture is delivered to the engine and how it breathes – in other words, the Engine Head design. The Engine Head has seen remarkable changes in the last few decades. Intake and head design have leapfrogged in the last decade culminating into what is called – variable valve timing technology (VVT). VVT gives the freedom for setting the valve timing over a wide spectrum of their activity to keep pace with changing engine RPM. This will produce optimum engine performance over a wide band of engine speed which will, in turn, contribute to high fuel efficiency and driving pleasure while also making the engine more environment friendly.

To get more power at high engine speeds one has to sacrifice low speed torque (resulting in an engine that is difficult to drive around town). For better high-speed torque (and more power) we would have to alter one or more of the components that affect engine breathing. The trick is to know what will give the best high-speed gain for the least low speed loss. VVT makes the size of all the components and the camshaft profile to get the best possible compromise between low speed torque and high-speed torque of the engine. Performance demands high capacity engines, and frugality – small efficient engines. So to achieve both on a single platform is impossible using conventional methods.

At low rpms, cams having small dwell periods are required because the engine does not need too much of forward thrust. However, at high rpm there is a need for more fuel flow and hence increased dwell period on the cam. Imagine that we are running an engine extremely slowly – at just 10 or 20 rpm, so it takes the piston seconds to complete a cycle. It would be impossible to actually run a normal engine this slowly; but imagine that if we could then we would want to grind the camshaft so that, just as the piston starts moving downward in the intake stroke, the intake valve would open. The intake valve would close right as the piston bottoms out. Then the exhaust valve would open right as the piston bottoms out at the end of the combustion stroke and would close as the piston completes the exhaust stroke. That would work great for the engine as long as it ran at this very slow speed.

When there is an increase in the rpm, however, this configuration of the camshaft does not work well. If the engine is running at 4,000 rpm, the valves are opening and closing 2,000 times every minute, or thirty to forty times every second. When the intake valve opens right at the top of the intake stroke, it turns out that the piston has a lot of trouble getting the air moving into the cylinder in the short time available (a fraction of a second). Therefore, at higher rpm ranges we want the intake valve to open prior to the intake stroke – actually back in the exhaust stroke – so that by the time the piston starts moving downward in the intake stroke, the valve is open and air moves freely into the cylinder during the entire intake stroke. For maximum engine performance at low engine speeds, the valves need to open and close differently than they do at higher engine speeds. If we put in a good low-speed camshaft, it hurts the engine’s performance at high speeds, and if we put in a good high-speed camshaft it hurts the engine’s performance at low speeds (and in extreme cases can make it very hard to start the engine).

Conventional powertrains don’t employ multiple camshafts and profiles. VVT is an electronic and mechanical system which allows the engine to effectively have multiple camshafts and cam profiles. As the engine moves into different rpm ranges, the engine’s computer can activate alternate lobes on the camshaft and change the cam’s timing. In this way, the engine gets the best features of low-speed and high-speed camshafts in the same engine. VVT has been embraced by several manufactures, each call it by their own names:

VarioCam/VarioCam Plus which is used on some of the Porsche engines,

MIVEC(Mitsubishi Innovative Valve timing and lift Electronic Control) which is used on the Mitsubishi engines,

VVT-i(Variable Valve Timing with Intelligence) and now VVTL-i (Variable Valve Timing and Lift with Intelligence) which is being used on the current Toyota and some Lexus engines,

VVL(Variable Valve Lift) which is used on the Nissan engines and also featured in the 350Z is the CVTCS (Continuously Variable Valve Timing System)

VANOS(Variable Onckenwellen Steuerung) which is used in the BMW engines and also the Double VANOS system on the new 3 Series and they are many more similar systems used by manufacturers such as Ford, Lamborghini and even Ferrari.

All these systems are ingenious but fail to cater to the intermediate power bands. In other words what they have is a limited number of cam-profiles. Realizing the limitations of the mechanical version of VVT, manufacturers came up with actuators operated hydraulically or electrically to actuate the valves instead of a set of cams. These gave comparatively infinite cam-profiles. The electrically operated actuators include electromagnets and solenoids which have faster response times than the hydraulically operated ones. Besides facilitating a large degree of freedom for setting the valve timing, improved combustion, lesser emissions, this technology does away with the timing chain thus improving mechanical efficiency. The actuators take various parameters as input from the rpm sensors, crank angle sensors etc. to actuate the valves at precise instances. But perhaps the biggest advantage of the actuator based systems is the Multi-Displacement Technology (MDT).

The simple fact is that when one needs only small amounts of power such as for crawling around the city, what one really needs is a smaller engine. In other words, an engine performs most efficiently when it’s working hard, so to force it to do the work of an engine half its size would result in its under utilization and efficiency loss. When a petrol engine is running with the throttle wide open, pumping losses are minimal. But at part-throttle the engine wastes energy trying to breathe through a restricted airway and the bigger the engine, the bigger the problem. Thus, deactivating half the cylinders at part load is much like temporarily fitting a smaller engine. If we consider a V6 engine, the MDT is activated at part throttle between 1000rpm and 3000rpm, when the actuators prevent the valves from opening. Hot gases are trapped in 3 of the 6 cylinders, compressing and expanding like giant air springs as the engine turns over and keeps the cylinders warm. But as long as the valves remain closed, only 3 cylinders consume fuel instead of 6. Engine efficiency is also improved because the 3 dormant cylinders are no longer working hard at sucking air into the engine, something that consumes a substantial amount of power.

Variable valve timing using camless systems is still in its nascent stage but once complete, it is going to take the world of internal combustion engines by storm. However, plenty of research needs to be done before unleashing such radical technology.

Leave a Reply

You must be logged in to post a comment.